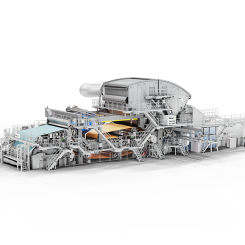

Kübler & Niethammer has invested some 19 million Euros modernising its production site in Kriebethal in Germany. Part of the modification process involved upgrading the technology in the dryer and press sections. Bellmer was responsible for the refurbishment, engineering, project management as well as disassembly and re-erection.

The aim of the project was both a sustainable increase in paper machine capacity and an improvement in competitiveness based on new, lighter packaging papers. Another target was to increase speed to 1,200 m/min and production volume by 30,000 t/a to 115,000 t/a.

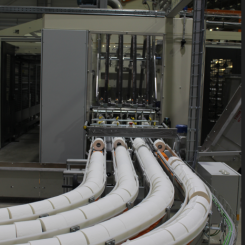

The rebuild included the installation of a completely new press section: a TURBOPress shoe press was specified to enhance the dry contents and thus reduce energy consumption in the dryer section. The scope of supply included rolls for the press section, parts for the paper and felt guiding system, frame elements for the new press section, pulpers and peripheral plant parts as well as the entire hydraulic control unit. The dryer section was upgraded to state-of-the-art technology.

The commissioning and startup processes were carried out on schedule, and feedback about the rebuild from Michael Moser, the project engineer at Kübler & Niethammer, was very positive.