Papermakers from several countries were brought all together – for the second time - in IBC Paper Training and Unitek Kağit’s training session in Istanbul held from the 22nd till the 24th of October. “Energy Saving in Papermaking” was centred around how to train the participants in understanding theoretical foundation of energy saving in papermaking methods, their implementation and importance.

The event provided an opportunity for its participants to test and develop collective energetic solutions and to assess the interoperability of their equipment, systems and procedures. The participants were then able after the training to fully understand the recommendations made by the expert lecturers in order to reduce the energy cost.

Developing interoperability for an effective use of the energy

“The training was well balanced between low and high investment solutions for saving energy. After those few days, I´ve got a very good idea about where and what to look for, I learned how to identify systems that could be improved to save energy, a lot of real practical solutions, some, let’s say, projects for mills with a limited financial potential. I was also introduced to new technologies, with enough details to make me feel confident to implement some large scale projects in the near future.” (Javier Guarnieri, Maintenance Chief, Smurfit Kappa, Argentina)

“I must say that I was more than pleased to spend those 3 days in Istanbul for your lectures. It was really an eye opener for me, since I realized that in the details of the paper process, you can find huge differences, especially in the energy saving and in the improvement of the paper quality. Our technology is relatively old and we have to do many steps to catch up on that. I must also thank IBC and Unitek for the warm hospitality and the well organized lectures.” (Margaritis Kapsalis, Maintenance Department, Komotini Paper, Greece)

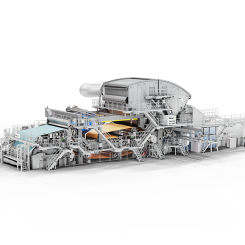

The training involved all areas of papermaking, with a key focus on production, maintenance and of course, energy.

Areas focused in the workshop

1- Energy trends and future implications

2- The different Energy Generations Options: Classical and new Development - Saving Energy in the Energy Production

3- Best Practice in Pumping to Gain Energy

4- Gain Energy in Electrical Drives by Optimization

5- Best Operating setting in Refining

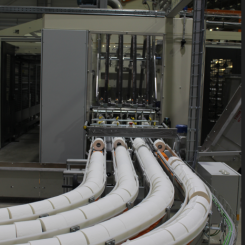

6- Optimization of existing vacuum systems

7- Focus on Turbo blower and Dewatering

8- Overview of Energy Savings in Drying Section

9- Controlling Point in Hood and Heat Recovery System

10- Steam Box to improve profiling and paper machine Efficiency

Expert lecturers and participants coming from all over the world

Eminent experts from MILS Processes (UK), Cutes Europe (Germany), META BV (Netherlands) and Heimbach/Paper Run (France) participated and presented through their lectures significant aspects about the specific chosen topic.

Held in English, the seminar gathered together 24 pulp, paper and tissue makers coming from worldwide: Argentina, Pakistan, Turkey, Singapore, Oman, Slovakia, Finland, Poland, Thailand, Iran and Greece: Smurfit Kappa, Century Paper, Oyka Pulp & Paper Mill, Lorentzen & Wettre (a member of the ABB Group), Al Karam, Mondi Group, EV Group Oy, Tul Kağit, SCG Paper, Pars Hayat, Modern Karton, Komotini Paper and Muratli Karton.