Recently, Bischof + Klein has commissioned new cast film line for the production of label films.

Uwe Wiegand, head of the Industrial Packaging division's marketing department, expresses his high expectations of this modern machine: "Energy and resource efficiency are important factors of sustainable production for Bischof + Klein. This line, which is very large even by our standards, scores points in this regard."

Bischof + Klein produces a wide range of films for the label industry. The majority of these are cast films. Customers use this film to manufacture a film laminate consisting of a siliconised substrate, e.g. polyester or paper, an adhesive and a cover material, the cast film from B+K. Together with the adhesive, this film subsequently forms the self-adhesive label.

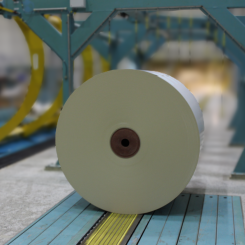

The films have to meet the highest optical and technical standards and are tailored to meet customers' individual requirements. They are provided with their particular flexibility and strength in special conversion steps. On the new cast film line, a firmly installed reel turner enables easier handling of the large reels, which weigh approx. 1.5 to 2.0 tonnes. Edge strips are directly recycled or further processed. Residual reels can also be recycled directly.

A new central refrigeration system supplies the line with high-quality cooling water, which circulates in a closed-loop, oxygen-free system. The re-cooling plants on the roof of the central cooling system also help to save significant volumes of energy. Up to an outside temperature of 16 degrees Celsius, they enable "free cooling" without the use of a compressor. Six additional silos supply the line with granules. A further cast film line for producing surface protection films was also installed and connected to the central cooling system this year.