The Italian company Eurovast has chosen Toscotec to supply new machinery for its Cartiera della Basilica Lugliano-Bagni di Lucca (LU) plant.

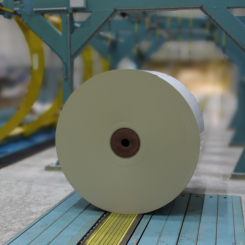

The machinery with a maximum production capacity of over 30.000 tonnes/year and winder paper size of 2800 mm will go into production in the first quarter of 2014.

Eurovast, a limited liability company managed by the Romano family and headed by entrepreneur Vincenzo Romano, is at the forefront of the Lucchese paper making industry. It has been working in the tissue market since the beginning of the ‘90s. The company currently has a production capacity of more than 70,000 tonnes per year with a total plant surface area of 36,000 m2 (three paper production plants and two processing plants located in the Lucca region in Bagni di Lucca, Villa Basilica, Lanciole, Capannori and Borgo a Mozzano). The production chain starts with the raw material and the fibres that are selected directly from Cartiera della Basilica. These are then transformed in the converting area of Eurovast SpA plants. Products are developed paying particular attention to health, safety, practicality and eco-sustainability.

The company has followed a dynamic and innovative path, which resulted in bringing “Rotolotto®” to the shelf in 1994. “Rotolotto” is the first single roll (typical of the industrial sector) for domestic use. For Eurovast this product was the driving force for growth and expansion that continues today with a complete range that includes the Fior di Carta and Fior di Carta Lifestyle® brands.

The new machinery is a Modulo plus crescent former in double press configuration and steel Yankee dryer TT Syd-3200MM with a maximum speed of 1500 m/min; it’s the ideal solution for meeting the demand for a high quality product together with the need for energy savings and emission reductions.

Care for the environment and the desire to install an eco-sustainable and innovative system were Eurovast’s determining factors in choosing to offer the consumer manufacturing excellence in a rapidly expanding sector.

The machinery will be installed at the existing site following the dismantling of the current machinery. Engineering services, assembly supervision, commissioning and start-up are all taken care of by Toscotec.