Iggesund Paperboard is advising customers to expect an upgrading of its folding box board, Incada.

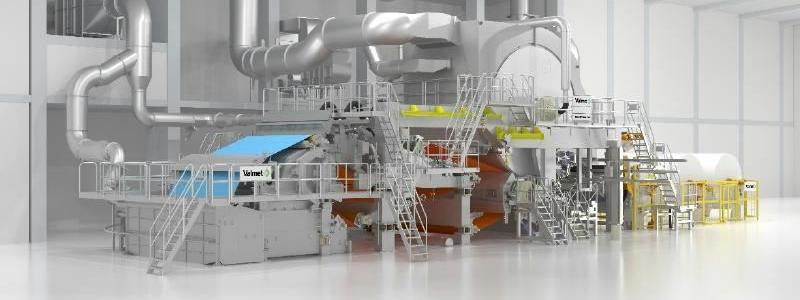

Incada, which is manufactured at Iggesund Paperboard's integrated mill in Workington, UK, is widely used for book covers, greeting cards and the packaging of food, cosmetics, chocolate, pharmaceuticals and tobacco products.

From this autumn Incada will be whiter and lighter and also have a number of improved properties affecting printability.

Incada Exel, which is more targeted as a packaging board, will also have improved stiffness. For grammages over 300 g/m2 this gain will be as much as 10 to 15 per cent.

“This enables our customers to reduce their packaging weights while keeping the same protection for the contents,” explains Robin Lewis, technical product manager for Incada.

The stiffness improvements have also led to a revision of Incada Exel’s grammage range to better suit the demands of the current customer base. Other substantial improvements have been made to the odour and taste properties so that Incada now comes in under the Robinson test’s detection limit of 0.6. The whiteness is increased by 7.5 units to 120 on the CIE scale. Improvements are found in the L value which is critical for colour reproduction. Runnability is also improved, so Incada will now be able to function even better in customers’ processes.

“Incada was introduced in 2001 and since then we’ve made many small changes to improve its quality,” Lewis says. “This is a big leap forward and it will definitely strengthen our market position.”

Iggesund Paperboard is a member of the Holmen Group and Europe's leading manufacturer of high quality virgin fibre paperboard for use in the packaging and graphics sectors. For more information visit: www.iggesund.com