Two years ago Stora Enso Sachsen GmbH was granted the sum of 30 million Euros to remove existing bottlenecks in the production line and to ready the system for future quality demands and developments. This way, Stora Enso Saxony safeguards its future in the drastically changing market place.

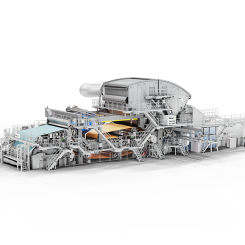

During the latest IMPS-symposium in the beginning of March in Münich, Production Manager, PM1, Dirk Schwarze from Stora Enso Sachsen, explained how the installation of a shoe press in the 3rd nip of the existing TriNip press and the installation of a new calender. Together these measures updated the system to the current state of the art. It laid the groundwork for further paper grades, e.g. phone-book grades, in addition to supporting the efficient production of the existing news print paper grades.

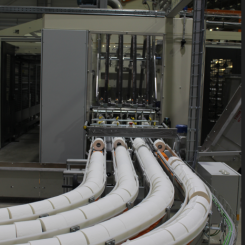

As part of the reconstruction, additional investments to save energy were also presented on the IMPS 2012. Such were high savings with generation of vacuum as well as realisation of measures to increase production efficiency reduction of machine breaks and increase machine cleanliness.

The mill in Sachsen, Germany produces newsprint from sorted household waste paper.