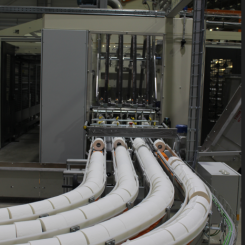

At this year’s IMPS - symposium in Munich the Director of Marketing, Petri Ristola, Metso Paper , Inc told the audience that the company has delivered five succesful spray sizing projects in total in Asia during last four years, three of them with two-sided spray. Metso has been developing the spray sizing technology for several years, and the work has its foundations in Metso’s long tradition with film sizing, water sprays and earlier spray coating developments. The technology is protected by several international patents and applications.

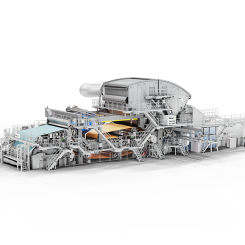

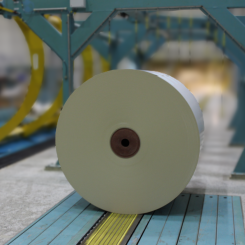

In 2008 Metso started up the first one-sided prototype unit of spray sizing for fluting in Korea.Spray sizing has a major role in Metso’s new OptiSizer family, to be launched to the market in 2012. After the start-up on May 12, 2012, the production line has produced sellable paper from day one and has since been able to successfully produce its full product range with the new equipment.

- Thanks to higher solids it is possible to use increased starch amounts without compromising production capacity.The paper gives and overview about the new spray sizing technology, including mill experiences related to savings in energy, as well as advantages in paper quality properties, Ristola explained.

Together with Papierfabrik Schoellershammer Europe’s first spray sizing unit has been started up for the mill’s 5-m-wide swing testliner and recycled fluting machine, PM 5, located in Düren, Germany. The new two-sided spraying unit was installed in an existing pond size press, originally delivered by Metso in 2005.