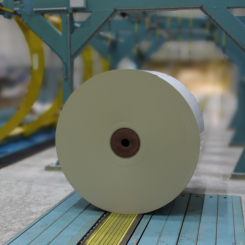

SGS has entered into an agreement with a global organization, located in Nelspruit, South Africa to provide non-destructive testing (NDT) on all new fabrication welds to be installed in a paper mill expansion project, in which a new plant is being built to replace the current facility.

Scheduled for a 20-day shutdown as of February 28, SGS began on location preparations on January 23. SGS currently has a staff of 12 on-site and that will increase to 40 for the shutdown phase and be adjusted accordingly for follow-up services until April 30.

From January to April, SGS will provide an extensive portfolio of NDT services for new fabrication welds in the construction of this new paper mill plant. The services will include radiographic, ultrasonic, particle, liquid penetrant and phased array testing.

Non-destructive testing services conducted by skilled SGS staff will ensure the safe and efficient operation of the Nelspruit paper mill equipment and assets by detecting defects before any damage can result and will verify compliance with all relevant international standards and regulations. SGS NDT services will provide the paper mill expansion project with complete or sample examinations using well-designed procedures and highly-trained, certified inspectors.

By applying the most effective NDT methods to investigate the integrity of the new fabrication welds to be used in the new paper mill facility, the SGS comprehensive range of NDT strategies will assist in monitoring weld quality, detect irregularities to avoid severe damage or non-compliance, save time and money through fast and effective testing and ensure the safe and reliable operation of the new paper mill plant. These SGS objectives will verify the quality of all new fabrication welds to be used in the project construction and guarantee the successful completion of the Nelspruit paper mill expansion project.