The main unit of the Rauhalahti plant has an efficiency of 140 MW district heating and 87 Mw electricity and capacity of its district heating boiler reach 40 Mw. The plant runs on peat, biomass and coal.

Since 2006, Jyväskylän Energiantuotanto Oy is testing the combustion of reed canary grass at the Rauhalahti CHP plant. The reed canary grass is always combusted as a fuel-mixture with peat or wood chips in the large scale combined heat and power (CHP) systems.

The reed canary grass is transported as bales to the Rauhalahti plant by local suppliers. The bales are chopped at the site and mixed to the main fuel. Earlier the plant produced even steam for the Kangas´ paper mill before it was closed.

Since its inception in 1986, the Rauhalahti power station has been controlled with a Damatic Classic automation system, which also was delivered by Metso. Combustion automation was upgraded later to the Damatic XD system, when the facility was rebuilt in order to apply fluidized bed combustion.

Fluidized bed combustion (FBC) is a combustion technology used in many power plants. The method suspend solid fuels in upward-blowing jets of air during the combustion process. The result is a turbulent mixing of gas and solids. The tumbling action, much like a bubbling fluid, provides more effective chemical reactions and heat transfer.

FBC technology was adapted to burn petroleum coke and coal mining waste for power generation in the early 1980s in the US. At that time, US regulations first provided special incentives to the use of renewable fuels and waste fuels.

FBC technology spread to other parts of the globe to address specific fuel quality problems. The technology has proved well suited to burning fuels that are difficult to ignite, like petroleum coke and anthracite, low quality fuels like high ash coals and coalmine wastes, and fuels with highly variable heat content, including biomass and mixtures of fuels.

The awareness of using biomass as fuel for production of heat and electricity has increased in recent years because it is a way to recycle waste and obtain a CO2-neutral fuel with relatively high-energy value at a low price.

Recycled biomass however, contains often impurities of plastics, paintings and metal components that lead to increased levels of heavy metals, chlorine and sodium compared to pure wood. These impurities often lead to problems with corrosion in the boiler, which in turn leads to reduced availability and efficiency and increased costs for the owner of the boiler..

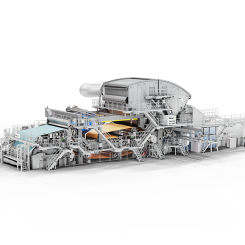

Today, numerous international companies, including Metso, are developing new technology that diminish corrosion and increase efficiency.

No interruption

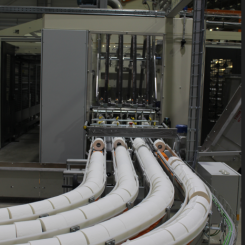

Now the complete plant automation system is renewed in accordance with Metso Automation system DNA, which features the latest technology. At the same time, the old PLCs in the burners, ash handling and water treatment and sootblowing processes will be replaced with Metso DNA.

- Because of the automation system, we have not had a single interruption in the plant during its existence, told the automation expert, Matti Niemelä, from regional energy company, Jyväskylän Energia.

The renewal project also includes a plant-wide energy management system, including multipurpose reporting applications as well as a fuel management system. Condition monitoring will be integrated with Metso DNA; it will also monitor the rotating equipment and predict its need for service.

The modernized automation system will have a connection to the Keljonlahti power plant that was started up in 2010. It is the company’s main production facility and also runs with Metso’s automation. As both of the plants will be connected to the Metso DNA user interface, the flow of information from one plant to another will be improved and joint control will be possible.

A user interface can be described as a link between the user and the hardware or software that the user is working with. The user interface function "typing" allows the user to directly affect the system.

Joint operators

Jyväskylän Energiantuotanto Oy is part of Jyväskylän Energia Group, which with its subsidiaries produces, sells and transfers electricity, heat and water in its networks. It also sells electricity to other network owners. In 2011, the group’s net sales reached EUR 185 million, and it employed about 250 people.

Metso is a global supplier of technology and services to customers in the process industries, including mining, construction, pulp and paper, power, and oil and gas. The company has 30,000 professionals based in over 50 countries.

According to Metsos spokeperson, Mylläri, the automation segment’s process automation and flow control solutions meet the growing needs of Metso’s customer industries to improve production process efficiency as raw materials, energy sources become scarcer and their costs climb.

Metso:s global network of service experts delivers business solutions to the customers, which according to Metso , improves their productivity, lower risks and optimize costs

Keljonlahti power station also lies outside Jyväskylä in central Finland. The plant, which has an installed production capacity of 209 MW, was expanded in 2008-2009. The Keljonkoski plant is primarily using peat, biomass and wood pulp (sawdust) as fuel.

Jyväskylän Energiantuotanto Oy is a part of Jyväskylä County Energy Group, which with its affiliates produces, sells and transmit electricity, heat and water in their networks. It also sells electricity to other network owners. During the last year, the Group's net sales reached 185 million Euros. The company employs approximately 250 people.

Increased profit despite orders decrease

The engineering group received new orders for 1.7 billion euros in april-June. It was 40 percent less than during the same period last year. The company explains that the decline in the preceding period was exceptionally strong.

Although the orders decreased the results increased for Metso. Profit before tax was now 149 million Euros, compared with 100 million Euros last year. Also the turnover increased by more than 20 percent to almost 1.9 billion Euros.

Sources: Jyväskylän Energiantuotanto Oy, Metso & HBL