“GL&V has provided a rebuild solution and after the preliminary discussions we decided to realize the project to rebuild the existing BeloitTM 12’6”x 10/20 Polydisc® 3000 disc filter for PM3 white water treatment”, says Mr. Alfred Kullik, , Engineering, Mitsubishi HiTec Paper Bielefeld Mill in Germany. Mr. Kullik was in charge of the PM3 rebuild project.

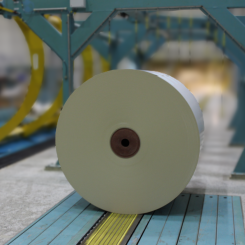

Mitsubishi HiTec Paper Bielefeld is a leading producer of specialty paper located in central Germany. The mill is known for its state-of-art technical expertise developing and manufacturing innovative products. Mitsubishi HiTec Paper Bielefeld GmbH produces 150.000 t/a of specialty papers with two paper machines. Paper brands produce by the mill are Giroform self copy paper, Jetscript inkjet paper, Thermoscript thermo paper and Supercote label paper.

“Disc Filter crashes began happening frequently. Our mill experienced three major crashes which caused outages of more than 24 hours each. Secondly, the old disk filter has produced only two qualities – cloudy and clear water.

We desired capability for super clear filtrate for shower cleaning water to eliminate a very old clarifier that was vulnerable to disruptions. So, we have been searching for a solution for a single installation that would deliver all three water qualities: cloudy, clear and super clear filtrates. We have a Hedemora® disc filter at the PM1 which has been providing our needs, but the bottle neck has been PM3,” says Alfred Kullik,

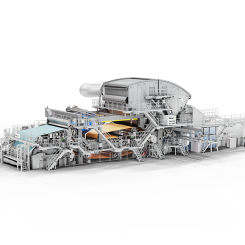

The No. 3 Paper Machine is a 5.800 mm wire width twin wire design equipped with an online coater. The design speed of the paper machine was already 1.200 m/minbefore the disc filter rebuild. Only the approach flow including the disc filter was not designed for the design speed of the paper machine. GL&V evaluated the BeloitTM filter and determined the necessary scope for a successful rebuild.

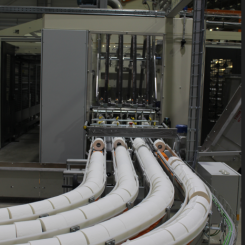

The GL&V project scope entailed:

Ten (•• 10) new high flow discs with grid cassette sectors provided with stainless steel fabrics and blank off parts

•• New filtrate valve with cloudy, clear and super clear filtrates

•• New additional feed box on the opposite side of existing feed box to improve feed flow to the sector

•• Extensions on each discharge chute for increased vat level

•• New knock-off pipe with inside brush cleaning system

•• Spare parts for the equipment

•• Option for 20 per cent more capacity

•• Bow screen shower water protection filter

The rebuild resulted in Mitsubishi eliminating a Krofta DAF clarifier once used for the production of super clear water for the paper machine showers. The bow screen was also included for additional protection to assure long fibers will not plug the showers.

The rebuild provided additional hydraulic capacity while eliminating half of the discs. In order to make the modification as cost effective as possible, Mitsubishi and GL&V worked together to plan the outage. GL&V designed and manufactured the new high flow cassette grid sectors, new filtrate valve and wear disc, and the new feed box specifically to suit the existing Bielefeld disc filter and to minimize the mill downtime.

During the outage, GL&V supervised local welders and fitters provided by Mitsubishi. The rebuild was completed during a 120 hours machine stop under GL&V supervision. GL&V Pulp and Paper, a division of the Canadian based company GLV Inc., is a global enterprise in technology and processes for manufacturing of pulp and paper as well as in production and treatment of fresh, process and waste waters.

The GL&V Pulp and Paper group is one of the largest suppliers of pulp and paper production equipment and a world leader in equipment rebuilds, upgrades and optimization.