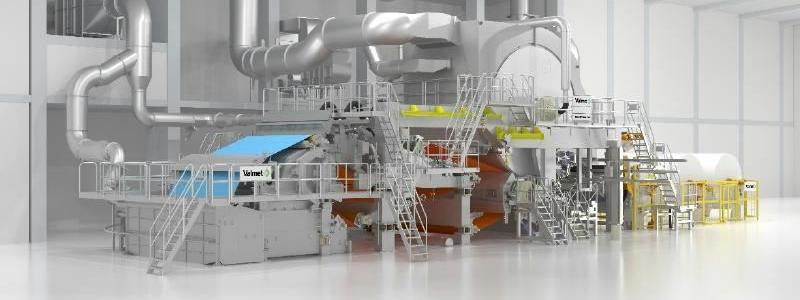

Mondi Extrusion Coatings has been in the business of process liners for the flexible foam industry for 30 years. The rising demand for flexible foam has triggered the development of an enhanced and even more efficient solution.

Within a short period of time, the engineers of Mondi have come up with a process liner that meets these demands and offers even more – a full service package including technical assistance, cost optimisation, reel width standardisation and a unique recycling scheme: Olmo 2.0+.

The original, tailor-made “Olmo paper” was developed by Mondi 30 years ago and helped the flexible foam industry to optimise their production and products. Now, Mondi has taken the next step towards better runnability, productivity and reduced environmental impact. The new process liner provides cost savings and enhances the quality of the product. Thanks to the full coverage of the foam block on all four sides, chemicals cannot evaporate and the foam block is protected from UV light as well as moisture. In addition, the entire production process is cleaner as the machine conveyors are shielded from sticky foam and the workers profit of a reduced toxic vapour exposure.