After seventeen months of conversion, hardwood specialist Danzer re-opened its location in Souvans, France on Thursday, September 7, 2017. By investing 13 million Euros in the site, Danzer responds to the ever-increasing demand for sliced wear layers in engineered hardwood flooring. From the beginning of 2018, the full capacity of about 20,000 m3 log volume will be processed in Souvans resource efficiently.

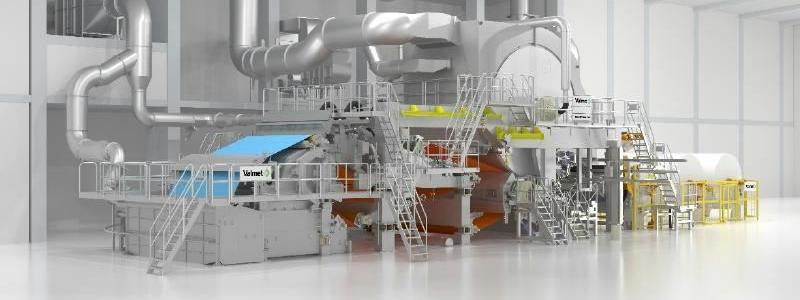

In May 2016 hardwood specialist Danzer started the conversion of its French site in Souvans. On Thursday, September 7, 2017, the staff celebrated the opening ceremony together with local representatives from politics and business as well as Danzer CEO Hans-Joachim Danzer. “In recent years, the global demand for engineered hardwood flooring has increased steadily – a trend that will continue. We have installed a new energy-saving boiler, our proprietary high-precision Danzer VS4000 veneer slicer and adequate drying kilns. Previous to the conversion, Souvans was exclusively producing veneer – now it is also a specialized production site for flooring deck layers. In spring 2017, we started a first test production; in the beginning of 2018 we expect to reach full capacity. An annual production volume of 20,000 m3 is planned for Souvans in the future, serving customers all over Europe. This is yet another milestone for our flooring business, without losing sight of our other hardwood activities.” Preceding the construction, the Danzer Supervisory Board approved a 15 million Euro investment plan for the thick-cut veneer expansion for the factories of Souvans, Melnik (Czech Republic) and Darlington (USA) in 2015. Prior to this, solely the plant in Melnik produced thick-cut veneers.

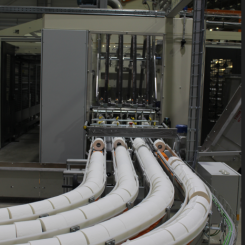

The distinctive feature of Danzer’s wear layers lies in their production. Deck layers are usually sawn but at Danzer they are sliced – exactly like Danzer does in the traditional veneer production process. “Our proprietary Danzer VS4000 slicers are capable of creating the product with a slicing process, completely eliminating the sawdust and saving roughly 30 to 40 percent of the valuable wood. Slicing is much more efficient here - the loss of wood is very low,” explains Rudi Heinzelmann, CEO of Danzer Veneer Europe.

As early as 2012, Danzer began producing sliced wear layers for engineered flooring – with increasing volume. Above all, the demand for deck layers in oak is high; a resource with an abundant supply in the Souvans region. “In addition to the many years of experience and the great know-how of our local employees, this was an important factor for the Souvans location,” says Hans-Joachim Danzer. “Due to our slicing technology and our proximity to the resource we work exceptionally efficiently. Additionally, thanks to our industrial approach, we are able to offer a high production volume of consistent quality and with short reaction times.”