Metsä Group's bioproduct mill in Äänekoski was started up on August 15, 2017. Valmet's delivery to the mill included a recovery boiler, pulp drying line, gasification plant, lime kiln, sulfuric acid plant, and mill-wide Valmet DNA automation system.

All the equipment delivered by Valmet represents the latest technology and are highly energy-efficient. The gasification technology and recovery boiler will maximize the use of bioenergy and make the pulp mill totally fossil fuel-free. The recovery boiler, pulp drying line and lime kiln are the largest in Europe.

Physically the largest of the Valmet delivered equipment is the recovery boiler. The boiler is designed for a capacity of 7,200 tds/d (tonnes dry solids a day). The Äänekoski recovery boiler has multiple high-power features, including patented heat recovery from flue gas to combustion air, enabling the mill to produce 260 MW of electricity and sell 1.4 times more electricity to the grid than it needs for its own operation.

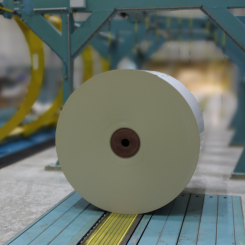

The produced pulp is dried in the pulp drying line, where the pulp web is formed, pressed and dried before being cut into bales.

Individual 250 kg bales are wrapped and consolidated into 2,000 kg units for transportation.

Valmet DNA automation system is the process control and information system for the whole bioproduct mill, and has machine and drive controls for the drying machine. It is also possible to expand the system with additional control and Industrial Internet systems.

At the biomass gasification plant bark is dried using a patented double-layer drying process with material recirculation. Dried bark is gasified to make product gas, which is then used as the fuel in the lime kiln.

Active lime is regenerated in the lime kiln using biofuels. A stationary product cooler is setting new standards for recovering process heat.