Schumacher Packaging Group will next year massively expand its Greven factory, opened only in 2014, thus doubling processing and warehousing capacities. The expansion, in which Schumacher Packaging is investing up to EUR 30 million, will also create 80 new jobs at the Greven factory. The substantial enlargement emphasises the strategic importance of the site for the packaging specialist: from its Greven base, Schumacher Packaging can speedily supply customers in north and west Germany and in the Benelux countries with all common corrugated cardboard packaging.

Schumacher Packaging originally invested EUR 45 million in the new factory building in the AirportPark FMO in Greven, close to Münster-Osnabrück Airport – and in June 2014 the state-of-the-art corrugated cardboard plant went into production. As Björn Schumacher, Managing Director of Schumacher Packaging Group explains: "Meanwhile, production at our Greven factory is running at full capacity with three shifts a day. That's why we're going ahead with the expansion now, a year earlier even than we orginally planned." The calls for tender to extend the production and warehouse facilities have already been issued. Work proper is due to start at the beginning of next year with completion by the third quarter of 2017.

At its Greven factory, Schumacher Packaging will then have two high-bay warehouses with a capacity of 31,000 pallet slots: the prerequisite for swift efficient logistics serving northwest Germany and the Benelux countries. The extension to 160 million square metres will also double Greven's production capacity. The long-term plan is to extend the current shop floor area of 30,000 square metres to as much as 100,000 square metres. This possibility of expansion also moved Schumacher Packaging Group to choose the AirportPark FMO in Greven as the site for its new factory in 2013.

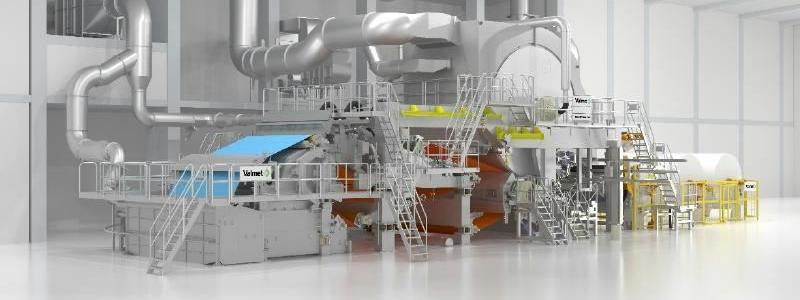

Corrugated cardboard is manufactured and processed into packaging on a 2.50 metre line at the Greven factory. Schumacher Packaging can thus produce all common types of corrugated cardboard packaging close to its customers. A special capability of the state-of-the-art plant in Greven is the production of continuous corrugated cardboard, which is very important to the furniture industry and steadily growing eCommerce sector. At its Greven factory, Schumacher Packaging can also manufacture laminated sheets and corrugated cardboard in parallel production.