Renewa Oy and Rottneros Bruk AB have signed a contract for a delivery of a new 20 MW biomass boiler in Rottneros, Sweden. The new boiler plant will produce renewable heat for drying of CTMP and groundwood pulp produced by Rottneros Bruk.

The new biomass boiler will supply the renewable heat needed for drying of the pulp and it will replace the existing boiler plant that has reached the end of its life cycle.

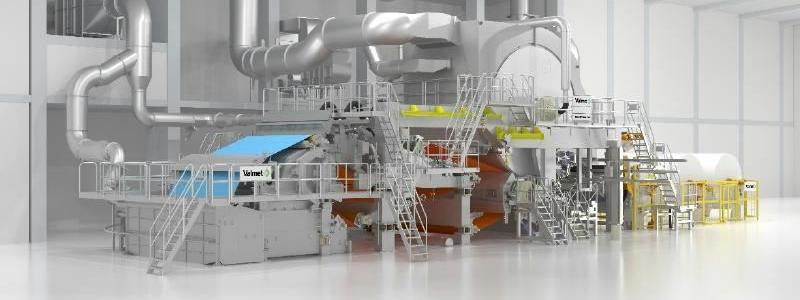

The new boiler will use Renewa´s ReneFluid bubbling fluidized bed (BFB) technology. The boiler plant will be designed for high availability use with paper mill sludge, saw dust and forest residues as fuels. Renewa’s scope of delivery includes fuel receiving station and BFB boiler plant including flue gas treatment based on electrostatic precipitator (ESP) and flue gas condenser.

“Rottneros has earlier this year announced a 98 MSEK investment program at Rottneros Bruk. We are running a number projects that will improve the energy efficiency and reduce use of fossil fuels at our mill in Rottneros. For the increased production of High Yield Pulps we need a new biomass boiler that has high availability, quick response to heat demand in our production process and low emissions. We also set a high value for the cost efficiency for the plant. After a detailed evaluation of different options, we decided to choose Renewa and their ReneFluid BFB-based boiler concept,” Olle Dahlin, Managing Director Rottneros Bruk AB, says.

Renewa Oy is a growing and internationally expanding expert in local bio-energy and heat and power plant technology.