Valmet announced that it will invest “several million euros” to develop its paper machine clothing production plant in Tampere, Finland in press felt production.

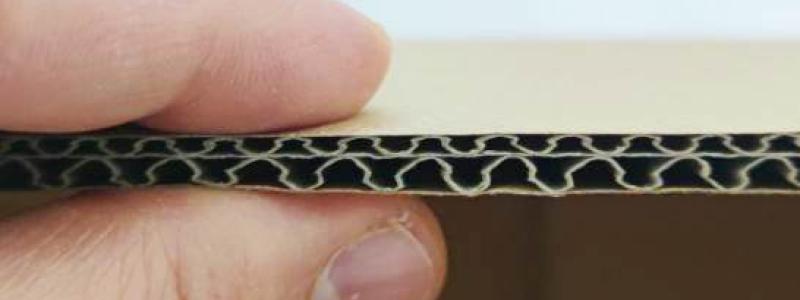

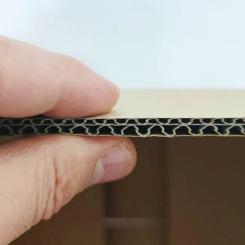

The project is being undertaken in order to improve the product technology and production capacity of seamed press felts for the paper, board, tissue and pulp drying machines.

The investment includes a new wide weaving loom, updating of some existing weaving looms and a new fiber opening and blending machinery.

The investment will allow it to meet the growing market needs as customers are inclined to move away from endless felts in older machines.

Valmet pointed out that the seamed felt market is growing in Europe, and especially in North America, where over 70% of the felts used in paper and board machines are endless.

Valmet also noted that the change from endless felts to seamed felts improves occupational safety and production efficiency at mills. The seamed felt installation is faster and takes much less manpower than installing an endless felt.

Valmet expects the project to be complete during the first quarter of 2017.