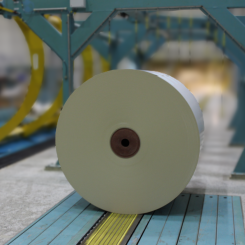

Valmet is introducing Bioneer press roll covers. The new innovative press roll covers are manufactured by applying recycled, renewable and bio-based raw materials, thereby enabling Valmet and its customers to reduce reliance on fossil resources.

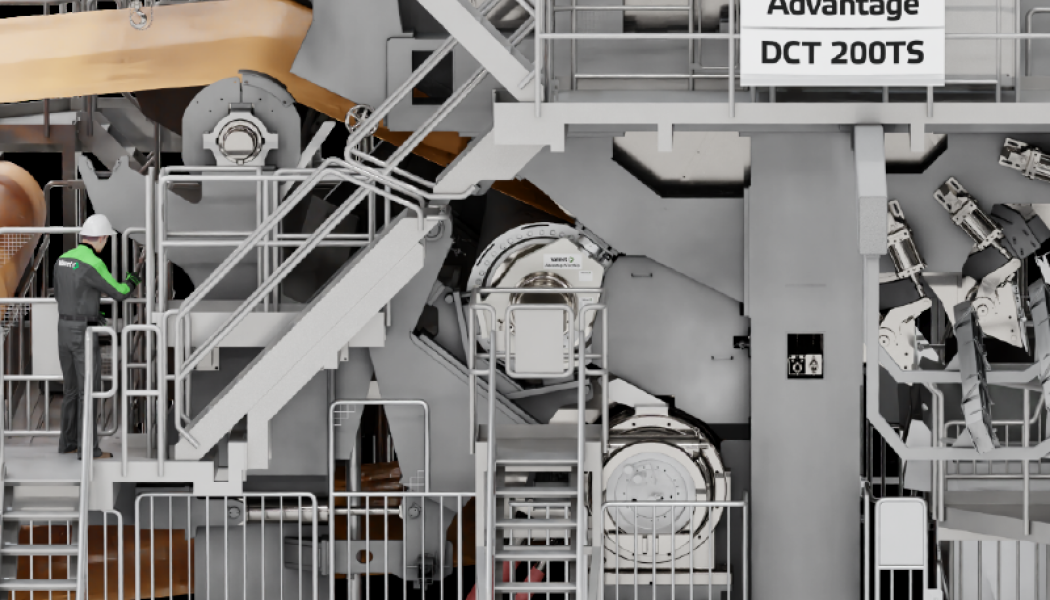

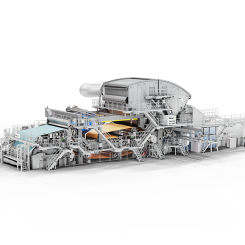

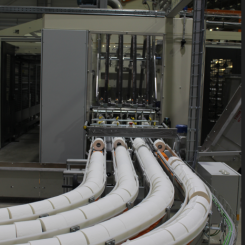

The Bioneer roll covers are designed for a wide range of press and suction roll applications on board, paper, tissue and pulp drying machines. These roll covers incorporate recycled, renewable or biobased materials without compromising durability, wear resistance, or dewatering performance.

“Our customers are increasingly looking for solutions that help them improve their machines’ performance while meeting their sustainability targets. With the Bioneer roll covers, we can offer both high-performance technology and verified climate impact data. This combination strengthens our role as a global roll cover technology leader and as a trusted partner in sustainability,” says Ulla Kanerva, Global Technology Manager, Roll Covers and Maintenance at Valmet.

First press roll covers with life cycle assessment data

Valmet’s Bioneer press roll covers are the first covers that are accompanied by product-specific life cycle assessment (LCA), providing customers with transparent and credible climate impact data.

For example, the Valmet Press Roll Cover PF Bioneer offers up to 12.2 percent lower cradle-to-gate CO₂ emissions compared to standard products. It is reached by using REDcert² -certified renewable and recycled materials through the mass balance approach.

“With the transparent LCA data, we can help our customers compare the climate impact of different products, make informed decisions, and demonstrate measurable progress towards their climate targets,” says Sanna Junttonen, Global Product Manager, Roll Covers and Maintenance at Valmet.