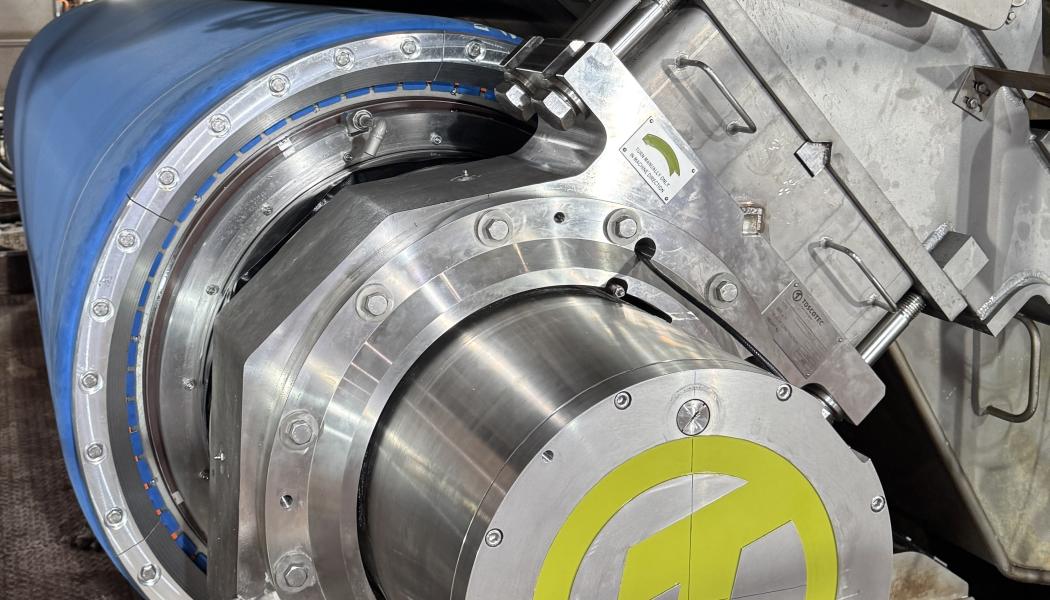

Fripa Papierfabrik Albert Friedrich has started up a TT NextPress shoe press supplied by Toscotec at their Miltenberg mill in Germany. The new shoe press has been operating efficiently for a few months and has fully achieved the targets of the rebuild.

Resulting from R&D activities in cooperation with Voith, Toscotec’s new generation design of TT NextPress shoe press delivers superior dewatering performances and energy savings. It ensures a stable after-press dryness rate of more than 45% on a tissue line operating at a speed of 2,100 m/min, thereby guaranteeing a substantial energy consumption reduction, due to the fact that the Yankee and the hoods use significantly less thermal energy to complete the drying process.

TT NextPress offers maximum operational accuracy thanks to multiple independent pressure zones. This design ensures a perfect fit between the shoe and previously existing old technology cast iron Yankee deformation and maximizes the lifetime of the machine’s clothing.

Christoph Maaß, Head of Paper Production at Fripa, says: “The main aim of the rebuild was to extend the lifetime of the paper machine clothing and improve machine uptime with stable production conditions. As things stand today, it can already be considered confirmed that both the felt and the sleeve lifetime has been extended enormously. As a result, the machine availability has improved positively. Another important effect is an improvement in the moisture profile, which leads to improved runability in the converting process.”

Stefano Raffaelli, Toscotec’s Project Manager, says: “We are very happy to have started such a positive cooperation with Fripa. With this successful shoe press rebuild, we achieved the project’s goals, and we are confident that we will see the benefits of the efficiency optimization going forward. Due to its high runnability and flexibility, TT NextPress is the perfect fit for rebuilds.”

About Fripa Papierfabrik Albert Friedrich

Founded in 1911, Fripa is one of the most modern and largest manufacturers of hygiene paper in Germany. It is headquartered in Miltenberg (Germany), where it operates three paper machines and several converting plants, and has two distribution warehouses in Düren and Berlin. It currently employs approximately 500 people and has a production capacity of >125.000 tons/year.